This Porous Paving Rocks

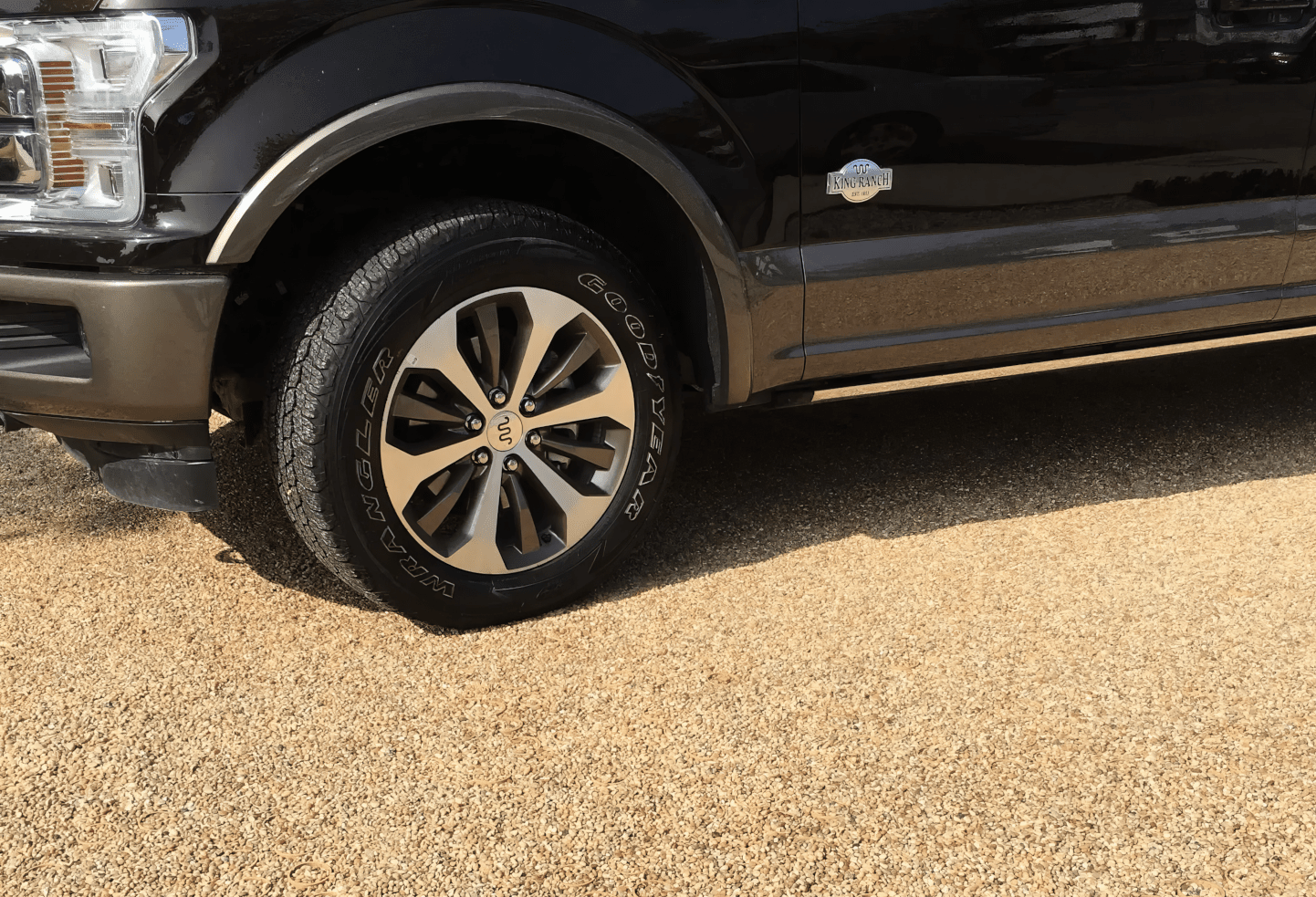

Created by a landscape architect, Gravelpave2® has been the trusted choice for low maintenance porous paving since 1991. With a compressive strength 5 times that of concrete, Gravelpave2 can support the weight of virtually any vehicle. Made from 100% recycled plastic, the lightweight and flexible rolls allow for quick and easy installation and can be easily trimmed for design versatility. Gravelpave2 is available in custom colors, making the possibilities limitless.

Gravelpave2 is available in five colors (Granite, Black, Tan, Gray and Terra Cotta). Granite is our newest color, and we highly recommend it, as it blends with just about any color of aggregate.

Gravelpave2 is great with curves and slopes, featuring filter fabric that will never come off, never disintegrate, will contain gravel, prevent weeds, and eliminate ruts.... all while made of 100% HDPE plastic! Anchors and washers are included with every order.